register for newsletter

get latest company news

Full servo sanitary pad making machine for India, featuring high speed, stable performance, and easy operation to ensure efficient and reliable production.

read more

This fully automated sanitary napkin production line is suitable for various types of sanitary napkins, including daytime, nighttime, ultra-thin, and winged types.

read more

This is an ordinary T shape baby diapers. Product advantage: basically boundless material loss and low cost. Applicable market: foreign country market. Machine operation: the machine operation difficulty is low, the production station of baby diaper product is less, and this equipment has been very mature.

read more

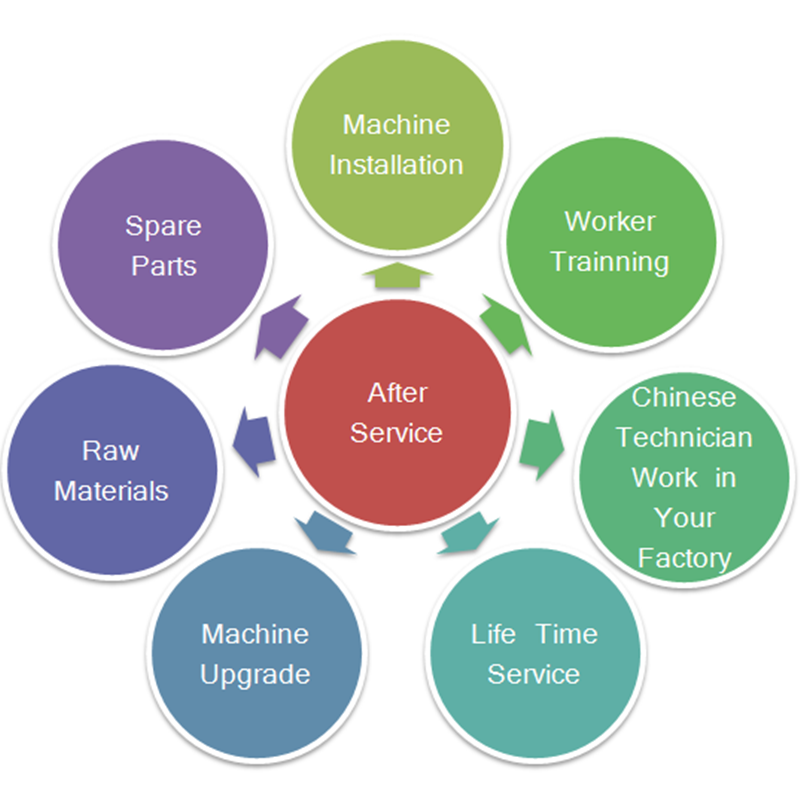

Full Servo High-speed Adult Menstrual Pants Packing Machine Main Technical Parameters of Menstrual Pants Packing Machine Packing Speed 60bags/min Packaging Product(L×W×H) (100-150)×(30-90)×(150-200)mm Packaging Material OPP、 PE、complex film Power Supply 380V/50HZ, 10m²* 5-core power cord Machine Size(L×W×H) 5800*6300*2450 Installed Power 11KW Air pressure 0.5-0.65MPa Weight 9800 Kg This packaging machine is used to pack menstrual pants products, which is a combination of an automatic stacker and two automatic packaging machines, which is capable of completing the bag feeding device, product grabbing, compression, and bag opening, bagging and sealing procedures that are automatically conveyed to the packaging machine, and then remove the cut waste. These sealed products are eventually conveyed along the conveyor belt. About RX Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team. More than 15 years experience focussing on hygiene machines. 10 CNC processing machine and 40 other processing machines. Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on. Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers. Factory Processing Map Packing and Packaging Diagram After-sales Service If you have interest in our product, please feel free to contact us!

read more

Fully Automatic High-speed Underpad Packaging Machine Main Technical Parameters of Underpad Packing Machine Packing Speed 50bags/min Packaging Product(L×W×H) (210-280)×(70-180)×(200-320)mm Packaging Material PE、complex film, nonwoven Bag Thickness 0.04-0.08mm Power Supply 380V/50HZ, 10m²* 5-core power cord Installed Power 24KW Air pressure 0.5MPa Weight 6000 Kg Under the fully automatic operation, this underpad packing machine can complete the process of product grabbing, compression, piece-counting, pushing, bag opening, bagging, sealing, and cleaning tailings. These sealed packages are conveyed along the conveyor belt. About RX Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team. More than 15 years experience focussing on hygiene machines. 10 CNC processing machine and 40 other processing machines. Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on. Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers. Factory Processing Map Packing and Packaging Diagram After-sales Service If you have interest in our product, please feel free to contact us!

read more

Fully Automatic High-speed Baby Diaper Packaging Machine Main Technical Parameters of Baby Diaper Packing Machine Packing Speed 40bags/min Packaging Product(L×W×H) (150-500)×(120-400)×(90-250)mm Packaging Material PE、complex film, nonwoven Bag Thickness 0.04-0.08mm Power Supply 380V/50HZ, 10m²* 5-core power cord Installed Power 25KW Air pressure 0.5~0.6MPa Air Consumption 0.6M³/min Weight 6650 Kg Under the automatic operation of the packing machine, the diapers are stacked neatly through the stacker according to the number of packaged pieces, and then pushed into the compression platform of the packaging machine. When the packaging machine detects the product, it will carry out the process of automatic product compression, conveying and stacking products, bag feeding, suction tape, bag opening, product bagging and other processes. About RX Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team. More than 15 years experience focussing on hygiene machines. 10 CNC processing machine and 40 other processing machines. Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on. Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers. Factory Processing Map Packing and Packaging Diagram After-sales Service

read more

800 PCS/Min Full Automatic Sanitary Napkin Machine Main Technical Parameters of Sanitary Pad Making Machine Item Sanitary napkin production line Output products winged sanitary napkin Control System Full servo / Semi servo / Frequency motor / Economical Part Description Most of the spare parts are under numerical control precisely processing. Key mechanical parts are under CNC processing. Main outsourcing parts are world famous brand. Operation Interface Industry PLC, with humanistic designing and optional collection for production record Certificates CE, ISO9001:2008, SGS Design Speed 1000 pcs/min Production Speed 800 pcs/min Overall Size of Equipment 31(L) * 2(W) * 2.5(H) m Machine Power Approx 240KW (380V, 50Hz) Optional Functions 1. Camera monitoring system (control online size checking, location inspecting, missing inspecting, stain spot scanning and so on.) 2. Material roll auto unwinding servo control 3. Material roll auto unwinding converter control 4. Automatic Packing machine 5. Full-servo control stacker (auto bagging machine) 6. Automatic bagging sealing machine Product Detail Images More sanitary napkin machine About RX Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team. More than 15 years experience focusing on hygiene machines. 10 CNC processing machine and 40 other processing machines. Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on. Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers. Factory Processing Map Packing and Packaging Diagram

read more

Introducing our "QuickFlow" Sanitary Napkin Machine - the ultimate solution for fast, efficient and versatile production of high-quality sanitary napkins. With its cutting-edge technology and user-friendly design, this machine sets a new standard in the industry. Boasting an impressive speed, the QuickFlow Sanitary Napkin Machine ensures swift production, saving valuable time and increasing productivity. Say goodbye to long waiting hours and hello to an uninterrupted workflow that meets the demands of today's fast-paced world. Not only does the QuickFlow Sanitary Napkin Machine offer exceptional speed, but it also offers unmatched versatility. Whether it's day use or night use sanitary napkins, our machine enables you to effortlessly switch between different sizes to cater to varying customer preferences. Enjoy the flexibility to adapt to market trends and meet the ever-changing needs of your customers. One of the standout features of the QuickFlow Sanitary Napkin Machine is its user-friendly design. Changing sizes has never been easier or quicker. With just a few simple adjustments, you can switch from producing smaller-sized daytime napkins to larger nighttime pads, ensuring a hassle-free manufacturing process. Additionally, our machine is engineered with precision and attention to detail, guaranteeing the production of sanitary napkins that are of the highest quality. Each napkin is crafted with care, ensuring optimal comfort and absorbency, providing women with the confidence and peace of mind they deserve. Invest in the QuickFlow Sanitary Napkin Machine today and experience the revolution in sanitary napkin production. It's time to streamline your manufacturing process, elevate your brand, and meet the ever-growing demands of the market. Don't settle for less when it comes to quality and productivity - choose QuickFlow, the ultimate solution for sanitary napkin production.

LS-1200 Non Woven Pouching And Embossing Machine is a professional hygiene material machinery.

brand:

RXitem no.:

RX-1200payment:

L/C 、T/Tproduct origin:

Chinacolor:

Customizedshipping port:

Xiamenlead time:

120 daysRX-1200 Non Woven Pouching And Embossing Machine

1. Machine application

Spunbond non woven and hot air through non woven

2. Basic Technical Information

| Machine design speed | 90m/min |

| Machine working speed | hot air through 60m/min |

| spun bond 70m/min | |

| Embossing width | 1200mm |

| Raw materials width | Max: 1240mm |

| Unwinding diameter | 1200mm |

| Rewinding diameter | 800mm |

| Machine direction | Right side |

| Machine size | 5500mm *3600mm *1500mm (L*W*H) |

| Air shaft | aluminium alloy |

| Guide roller | Hard oxidation treatment |

| Pneumatic component | Air TAC |

| Machine capacity | 60 KW |

| Machine power | three phase 380V 50HZ |

| Air compressor ( customer prepare) | 5.5 kw . 0.67m³ /min |

| 0.8 MPA |

3. Machine parts

| Fame part | 3 sets |

| Unwinding part | 1 set |

| Heating part | 1 set |

| Embossing part | 1 set |

| Cooling part | 2 sets |

| Traction part | 1 set |

| Slitting part | 2 sets |

| Rewinding part | 1 set |

| Driving and control system | 1 set |

Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team.

More than 15 years experience focussing on hygiene machines.

10 CNC processing machine and 40 other processing machines.

Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on.

Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers.

LE-120-PAE Non Woven Punching And Embossing Machine

LE-120-PAE Non Woven Punching And Embossing Machine

LE-120-PAE non woven punching and embossing machine is a hygiene materials machinery.

RX-1200 Non Woven Pouching And Embossing Machine

RX-1200 Non Woven Pouching And Embossing Machine

RX-1200 Non Woven Pouching And Embossing Machine is a professional hygiene material machinery.

High Quality Non Woven Embossing and Rewinding Machine

High Quality Non Woven Embossing and Rewinding Machine

The process method of Non Woven Embossing and Rewinding Machineis is unwinding--embossing--cutting--rewinding

High Quality Diaper Non Woven Punching And Embossing Machine

High Quality Diaper Non Woven Punching And Embossing Machine

LE-120-PAE non woven punching and embossing machine is a hygiene materials machinery.

Full Servo High Speed Disposable Adult Diaper Machine Price

Full Servo High Speed Disposable Adult Diaper Machine Price

Full Servo adult diaper machine, which can make different size adult diaper in high speed

PP Frontal Tape for Disposable Diaper Raw Materials

PP Frontal Tape for Disposable Diaper Raw Materials

The frontal tape is used to facilitate multiple repositioning of the lateral tape without tearing the backsheet as baby diaper raw materials.

HCH Second Hand Full Servo I & T Shape Baby Diaper Machine

HCH Second Hand Full Servo I & T Shape Baby Diaper Machine

HCH Second hand full servo automatic I & T shape baby diaper machine

Semi-Automatic Adult Baby Diaper Packing Machine

Semi-Automatic Adult Baby Diaper Packing Machine

This machine is semi-auto packing machine, used to pack adult diaper, baby diaper, santiary napkin etc.

High Precise Stripping Strength Tester for Sanitary Napkin and Diaper

High Precise Stripping Strength Tester for Sanitary Napkin and Diaper

This tester is suitable for testing the peeling strength of sanitary napkins pads, and can also be used for tensile strength, tearing strength, sealing strength and other performance tests of the outer packaging of sanitary products. It is widely used in testing organizations of sanitary products enterprises.

RX-CD 150 Semi Automatic Economic Type Under Pad Machine

RX-CD 150 Semi Automatic Economic Type Under Pad Machine

NS-CD 150 semi automatic economic type under pad machine

Copyright © Quanzhou Ruoxin Machinery Co.,Ltd. All Rights Reserved.

friendly links :

scan to wechat