register for newsletter

get latest company news

Full servo sanitary pad making machine for India, featuring high speed, stable performance, and easy operation to ensure efficient and reliable production.

read more

This fully automated sanitary napkin production line is suitable for various types of sanitary napkins, including daytime, nighttime, ultra-thin, and winged types.

read more

This is an ordinary T shape baby diapers. Product advantage: basically boundless material loss and low cost. Applicable market: foreign country market. Machine operation: the machine operation difficulty is low, the production station of baby diaper product is less, and this equipment has been very mature.

read more

Full Servo High-speed Adult Menstrual Pants Packing Machine Main Technical Parameters of Menstrual Pants Packing Machine Packing Speed 60bags/min Packaging Product(L×W×H) (100-150)×(30-90)×(150-200)mm Packaging Material OPP、 PE、complex film Power Supply 380V/50HZ, 10m²* 5-core power cord Machine Size(L×W×H) 5800*6300*2450 Installed Power 11KW Air pressure 0.5-0.65MPa Weight 9800 Kg This packaging machine is used to pack menstrual pants products, which is a combination of an automatic stacker and two automatic packaging machines, which is capable of completing the bag feeding device, product grabbing, compression, and bag opening, bagging and sealing procedures that are automatically conveyed to the packaging machine, and then remove the cut waste. These sealed products are eventually conveyed along the conveyor belt. About RX Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team. More than 15 years experience focussing on hygiene machines. 10 CNC processing machine and 40 other processing machines. Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on. Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers. Factory Processing Map Packing and Packaging Diagram After-sales Service If you have interest in our product, please feel free to contact us!

read more

Fully Automatic High-speed Underpad Packaging Machine Main Technical Parameters of Underpad Packing Machine Packing Speed 50bags/min Packaging Product(L×W×H) (210-280)×(70-180)×(200-320)mm Packaging Material PE、complex film, nonwoven Bag Thickness 0.04-0.08mm Power Supply 380V/50HZ, 10m²* 5-core power cord Installed Power 24KW Air pressure 0.5MPa Weight 6000 Kg Under the fully automatic operation, this underpad packing machine can complete the process of product grabbing, compression, piece-counting, pushing, bag opening, bagging, sealing, and cleaning tailings. These sealed packages are conveyed along the conveyor belt. About RX Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team. More than 15 years experience focussing on hygiene machines. 10 CNC processing machine and 40 other processing machines. Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on. Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers. Factory Processing Map Packing and Packaging Diagram After-sales Service If you have interest in our product, please feel free to contact us!

read more

Fully Automatic High-speed Baby Diaper Packaging Machine Main Technical Parameters of Baby Diaper Packing Machine Packing Speed 40bags/min Packaging Product(L×W×H) (150-500)×(120-400)×(90-250)mm Packaging Material PE、complex film, nonwoven Bag Thickness 0.04-0.08mm Power Supply 380V/50HZ, 10m²* 5-core power cord Installed Power 25KW Air pressure 0.5~0.6MPa Air Consumption 0.6M³/min Weight 6650 Kg Under the automatic operation of the packing machine, the diapers are stacked neatly through the stacker according to the number of packaged pieces, and then pushed into the compression platform of the packaging machine. When the packaging machine detects the product, it will carry out the process of automatic product compression, conveying and stacking products, bag feeding, suction tape, bag opening, product bagging and other processes. About RX Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team. More than 15 years experience focussing on hygiene machines. 10 CNC processing machine and 40 other processing machines. Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on. Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers. Factory Processing Map Packing and Packaging Diagram After-sales Service

read more

800 PCS/Min Full Automatic Sanitary Napkin Machine Main Technical Parameters of Sanitary Pad Making Machine Item Sanitary napkin production line Output products winged sanitary napkin Control System Full servo / Semi servo / Frequency motor / Economical Part Description Most of the spare parts are under numerical control precisely processing. Key mechanical parts are under CNC processing. Main outsourcing parts are world famous brand. Operation Interface Industry PLC, with humanistic designing and optional collection for production record Certificates CE, ISO9001:2008, SGS Design Speed 1000 pcs/min Production Speed 800 pcs/min Overall Size of Equipment 31(L) * 2(W) * 2.5(H) m Machine Power Approx 240KW (380V, 50Hz) Optional Functions 1. Camera monitoring system (control online size checking, location inspecting, missing inspecting, stain spot scanning and so on.) 2. Material roll auto unwinding servo control 3. Material roll auto unwinding converter control 4. Automatic Packing machine 5. Full-servo control stacker (auto bagging machine) 6. Automatic bagging sealing machine Product Detail Images More sanitary napkin machine About RX Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team. More than 15 years experience focusing on hygiene machines. 10 CNC processing machine and 40 other processing machines. Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on. Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers. Factory Processing Map Packing and Packaging Diagram

read more

Introducing our "QuickFlow" Sanitary Napkin Machine - the ultimate solution for fast, efficient and versatile production of high-quality sanitary napkins. With its cutting-edge technology and user-friendly design, this machine sets a new standard in the industry. Boasting an impressive speed, the QuickFlow Sanitary Napkin Machine ensures swift production, saving valuable time and increasing productivity. Say goodbye to long waiting hours and hello to an uninterrupted workflow that meets the demands of today's fast-paced world. Not only does the QuickFlow Sanitary Napkin Machine offer exceptional speed, but it also offers unmatched versatility. Whether it's day use or night use sanitary napkins, our machine enables you to effortlessly switch between different sizes to cater to varying customer preferences. Enjoy the flexibility to adapt to market trends and meet the ever-changing needs of your customers. One of the standout features of the QuickFlow Sanitary Napkin Machine is its user-friendly design. Changing sizes has never been easier or quicker. With just a few simple adjustments, you can switch from producing smaller-sized daytime napkins to larger nighttime pads, ensuring a hassle-free manufacturing process. Additionally, our machine is engineered with precision and attention to detail, guaranteeing the production of sanitary napkins that are of the highest quality. Each napkin is crafted with care, ensuring optimal comfort and absorbency, providing women with the confidence and peace of mind they deserve. Invest in the QuickFlow Sanitary Napkin Machine today and experience the revolution in sanitary napkin production. It's time to streamline your manufacturing process, elevate your brand, and meet the ever-growing demands of the market. Don't settle for less when it comes to quality and productivity - choose QuickFlow, the ultimate solution for sanitary napkin production.

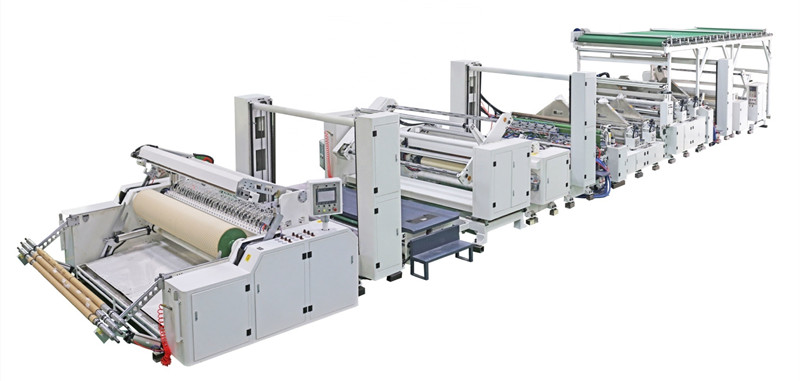

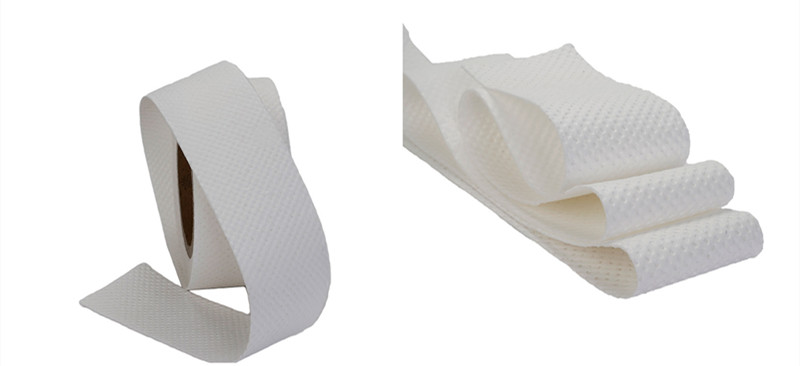

This machine is used to making ultra thin sap paper for diaper & sanitary napkin absorbent core

payment:

L/C 、T/Tproduct origin:

Chinacolor:

Customizedshipping port:

Xiamenlead time:

100 daysFull Automatic SAP Paper Sheet Making Machine for Diaper and Sanitary Napkin

1.This production line could realize a link production with fluffy nonwoven production equipment, effective control the product lose in the productive process. Promote the production efficiency.

2. Adopt modular construction design, PLC program control, integrated type HMI operation.

3. All main line drive by global famous brand frequency motor , SAP spread drive by Mitsubishi servo motor. Precision metrological materials spreading amount, measuring accuracy can control within ±3%.

4. Two section type unwinding mechanism with on-line nonwoven production equipment, non-stop, no need to speed down and auto splicing materials, reduce materials lose and time waste in the roll changing process. Effective capacity improvement. We configure patent structure for materials connection scheme. While ensure the strength of connecting materials, materials tails’ length is getting effective controlled.

5. Full automatic winding mechanism with auto roll changing function, alloy cutting knives online slitting product to be predetermined dimension.

1. Max design speed:70 m/min

2. Normal working speed: 30-60 m/min(no need to speed down while splicing)

3. Effective laminating width:2400 mm

4. Roller surface width: 2600 mm

5. Single-layer sap spreading amount:50g – 180 gsm

6. SAP spreading accuracy deviation : ±3%

7. Unwinding diameters for airlaid paper: ø1200mm

8. Winding diameters for laminated materials: ø1200mm

9. Finished product weight: 200-450 gsm , depend on client’s raw material

10. Electric control scheme: main line drive adopts closed-loop frequency converter adjust speed, sap shaft adopts servo drive

11. Overall dimension: 24500mm*4500mm*3500mm(L*W*H)

Fast High Quality Baby Diaper Production Line for Sale

Fast High Quality Baby Diaper Production Line for Sale

Fast High Quality Baby Diaper Production Line Functions and features of baby diaper machine 1) The baby diaper machine can produce 4 sizes of I shape, T shape baby diapers. 2) Crusher system adopts hard alloy Saw blade head, can crush all kinds of fluff pulp, crushing capacity can up to 600-1000KGS/Hour. 3) Double fluff core drum forming system ,with long fiber and better absorbent capacity. 4) SAP feeding adopts frequency converter controlling system. Parameter of grams can be set on the touchable screen. 5) The machine produce I shape or T shape type baby diapers, which include the following devices: a) Fluff pulp wrapping and continuous pressing unit. b) Top sheet non-woven feeding system c) Leg cuff system d) Bottom film feeding system e) Frontal tape feeding and side tape feeding system f) Side tape inner-folding system g) Arc shape cutting system h) Product vertical folding and product final cutting system i) Product arranging-out. Optional device 1: Perfume spraying unit 2: Wetness display function Main technical parameters of baby diaper machine 1) Model: YNK450-HSV 2) speed: 400-450m/min 3) capacity: 330KW (380V 50Hz) 5) Breaker Capacity: 400A 6) Electric wire: 3x70mm2+1x25 mm2+1x16mm2 7) Machine size: (31*8*5.5)M(L×W×H) 8) Machine weight: 28.5T 9) Air compressor:1.5m3/min 10) Product size: S, M, L, XL, 11) Container: 2x40HQ About RX Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team. More than 15 years experience focussing on hygiene machines. 10 CNC processing machine and 40 other processing machines. Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on. Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers. Factory Processing Map Packing and Packaging Diagram After-sales Service

RX-HY600-HSV Semi Servo Type Under Pad Machine

RX-HY600-HSV Semi Servo Type Under Pad Machine

RX-HY600-HSV semi servo type under pad machine is a full auto specialized in manufacturing under pad machine.It can do sizes:400*600mm, 600*600mm and 900*600mm.

LF-400-ME Diaper Cloth Like Backsheet Lamination Machine(Full Servo)

LF-400-ME Diaper Cloth Like Backsheet Lamination Machine(Full Servo)

LF-400-ME diaper cloth like backsheet lamination machine(full servo) is a professional manufacture hygiene materials machinery.

Used China Manufacture Automatic High Speed Baby Pull-UPS Pants Machine

Used China Manufacture Automatic High Speed Baby Pull-UPS Pants Machine

Used Automatic High Speed Baby Pull-UPS Pants Machine Main Fuction Features 1.full-automatic with PLC control and touch screen; 2.High-speed teeth-like crusher; 3.Web-wheel molding; 4.SAP auto adding with amount control; 5.Servo unwinding,auto-tension control and auto splicing for raw material; 6.Auto reject for wasted & rejected product,auto detect & alarm for material exhausted; 7.Phase adjusting during running without stop; 8.Diaper tri-folding or bi-folding; 9.Diaper auto counting & stacking. Main Technical Parameter Designed production speed 600 pieces/min Stable production speed 500 pieces/min(or as per customers designed) Machine power three-phase five-wire(380V, 50HZ) Machine capacity about 300-350KW(exclude hot melt applicators and air compressor Machine size 30.0m*7.0m*3.5m(L*W*H)( (Can be customized) Machine weight about 60 Ttons(whole production line) Air pressure 0.6-0.8Mpa Machine Details of baby pull-up machine Condition Used Year 2007 year Product Type Diaper Machine Processing Type Full-automatic high speed Pull-ups Machine (LLK500-SV) Place of Origin Fujian, China (Mainland) Model Number YNK500-SV Certification CE,ISO certificates Warranty 1 year After-sales Service Provided Engineers available to service machinery overseas Stable: yes Size of diaper: S, M, L, XL Finished product: baby diaper Control system full-automatic Waste rate less than 2% Operators 6-8 operators including packing baby diaper Packaging & Delivery for baby pull-ups machine Packaging Details: wooden cases and plastic film for full automatic high speed pull-ups making machine Delivery Details: within 120days pull-ups Machine Our Service Excellent After-sale Service 1. You can send technician to learn operate machine before the machine delivery for 1- 2 month. We can offer food and accommodation. 2. When machine arrives your workshop, we will send technician installing, testing the machine and training your workers. 3. If you need one Chinese technician work for you, we can help you find one work for you. 4. Life-long after service for Full-servo automatic baby diaper manufacturing machine. 5. We are Chinese Listed company since Nov.30th, 2012, 035007, we have ISO certificate, certificate of utility model patent, patent for invention for machine etc, you can trust we are your best supplier. 6. We can do full support for your complete project, from machine's manufacturing and installment, supplying raw materials, designing your factory layout, workers training to final production. 7. We have served customers from over 100 countries in the world untill now. 8. We can offer you very good machines and service at good price. (we have our own parts processing workshop) 9. We are factory manufacturer, not trading company. FAQ Q: Are you a machine manufacture or trading company? A: We are a machine manufacture of baby diaper machine, adult diaper machine, pull on diaper machine, sanitary napkin machine, panty liner machine,underpad machine, pet pad machine, breast pad machine and Underarm pad machine. Q: What is the delivery time for a set machine? A: 120 days as a fastest delivery time. As a manufacture, we need time to make our machine perfect in every taspect. Q: What is your term of payment? A: T/T is our first choice, L/C at sight is ok as well. Q: How long is the warranty period? A: one year after the testing finished at the buyer's workshop. Q: Will you send the engineer to install machine and train our workers in our factory A: of course. We will send engineer to installing and training. But the salary and accommodation of technician will be on the buyer' s side. you can sent your engineers to our factory for training, we will offer accommodation. Q: How long can I get the machine? A: we will begin to make your machine once we receive your 30% down payment. around 4 month, we will finish the produce and ask the buyer to check the machine and pay for the rest money. about 10 days for packing the machine, arrangment of shipping and customs clearance. some days for the shipping and some days for the customs clearance in the buyers country. Finally, you can get the machine. Q: Can I buy raw material from your company? A: yes. we have a trading company, which cooperate with us for many years. we can help you to find raw material.

Disposable Dog Pad Pet Pad Making Machine Price

Disposable Dog Pad Pet Pad Making Machine Price

Disposable Dog Pad Pet Pad Making Machine Main Features of Pet Pad Machine 1. Produce different sizes of under pad 2. The quantity of SAP and fluff pulp can be adjusted freely 3. Raw materials automatic unwinding system, automatic splicing units, automatic rejection units, automatic web guard system. 4. Under pad machine is attached with fully automatic packing machine (stacker), make packing simpler and save labor force 5. Under pad machine equipped with production door 6. Touchable Screen: Machine switch on/off, running speed, time, counting pieces, parameter setting, alarm, error display, error enquiry(functions setting appear on screen are different according to different machine type) Configurations of Pet Pad Making Machine Condition: New semi-servo underpad production machine Product Type: Underpad making Machine Processing Type: Pulp Molding Machine Place of Origin: Fujian, China (Mainland) Model Number: CD150-HSV Voltage: 380v, 50HZ, three-phase five-wire Power(W): about 350 kw Dimension(L*W*H): 22m*8m*3.5m ( L*W*H) Weight: 30Tons Certification: ISO, certificate of utility model patent Warranty: 1 year After-sales Service Provided: Engineers available to service machinery overseas Machine type: full-servo underpad production machine Designed speed: 150 meterss/min Stable production speed: 100 meters /min Diaper size: S, M, L, XL Control system: semi-servo control Packaging system: Equipped with the stacker at the request of client Efficient rate: ≥ 85% Reject rate: ≤2% Air pressure: 0.6-0.8 Mpa About RX Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team. More than 15 years experience focussing on hygiene machines. 10 CNC processing machine and 40 other processing machines. Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on. Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers. Factory Processing Map Packing and Packaging Diagram After-sales Service

Fast Disposable Hospital Nursing Pad Machine

Fast Disposable Hospital Nursing Pad Machine

Fast Disposable Hospital Nursing Pad Machine Main Features of Nursing Pad Machine 1. Side-gather & lamination panty liner can be produced; 2. Touch screen is adopted for man machine conversation; 3. Servo adopted for main machine drive; PLC control; 4. Active unwinding and splicing units are adopted for raw material; 5. Auto detects & alarm for material exhausted; auto reject for waste caused by splicing; 6. Square supports are adopted for frame of rotary bodies & cutters; 7. Protective door is equipped. Products Structure 1. 3-ply: PE film, fluff pulp, non-woven fabrics 2. 5-ply: PE film, lower tissue, fluff pulp, upper tissue,non-woven fabrics Configurations of Under Pad Making Machine The Comparison of Four Kinds of machines Part 1 Parameter Model YC-CD 150 YC-CD200-FC YC-CD200-HSV YC-CD250-SV Name Economic type Frequency type Semi servo type Full servo type Automaticly Semi-auto Full auto Full auto Full auto Product size (Customlized) 400*600mm 600*600mm 900*600mm 400*600mm 600*600mm 900*600mm 400*600mm 600*600mm 900*600mm 400*600mm 600*600mm 900*600mm Design speed 150m/min 200m/min 200m/min 250m/min Production speed 100m/min 150m/min 150m/min 200m/min Power 80KW 150 KW 150 KW 180KW Power source 380V, 50HZ, 3 phase 5 wire 380V, 50HZ, 3 phase 6 wire 380V, 50HZ, 3 phase 7 wire 380V, 50HZ, 3 phase 8 wire Efficiency >=85% >=88% >=88% >=88% Rejection rate <= 3% <= 2% <= 2% <= 2% Machine weight 45 Ton 60 Ton 60 Ton 60 Ton Machine size 18m * 3m * 3m 20m * 3m * 3m 20m * 3m * 3m 20m * 3m * 3m Operating size 20m * 7m * 5m 25m * 7m * 5m 25m * 7m * 5m 25m * 7m * 5m Air pressure 0.6-0.8MPA 0.6-0.8MPA 0.6-0.8MPA 0.6-0.8MPA Machine color Customlized Customlized Customlized Customlized Machine direction Customlized Customlized Customlized Customlized Part 2 Electric part PLC No have Mitsubishi / Simense Mitsubishi / Simense Mitsubishi / Simense Touch screen × Mitsubishi / Simense Mitsubishi / Simense Mitsubishi / Simense Unwinding type × Initiative Initiative Initiative Materials shaft stand Machanical shaft stand Pneumatic shaft stand Pneumatic shaft stand Pneumatic shaft stand Tension control system × √ √ √ Unwinding motor × Invertor motor Invertor motor Servo motor Web guider Manual Digital & Auto Digital & Auto Digital & Auto Driving system One main motor Three main motors Servo motor independently control Servo motor independently control Detective Manual Auto Auto Auto Materials splicing Manual Auto Auto Auto Safety door Back Back & Front Back & Front Back & Front Flat belts China Switzerland Switzerland Switzerland Timing belts China USA USA USA Bearing China Japan Japan Japan About RX Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team. More than 15 years experience focussing on hygiene machines. 10 CNC processing machine and 40 other processing machines. Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on. Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers. Factory Processing Map Packing and Packaging Diagram After-sales Service

RX-BZ-204B full servo full automatic baby diaper packing machine

RX-BZ-204B full servo full automatic baby diaper packing machine

full servo full automatic baby diaper bagging machine

Copyright © Quanzhou Ruoxin Machinery Co.,Ltd. All Rights Reserved.

friendly links :

scan to wechat