Egyptian Researchers Extract First Long Textile Fiber from Date Palm Byproducts

on July 22,2020.

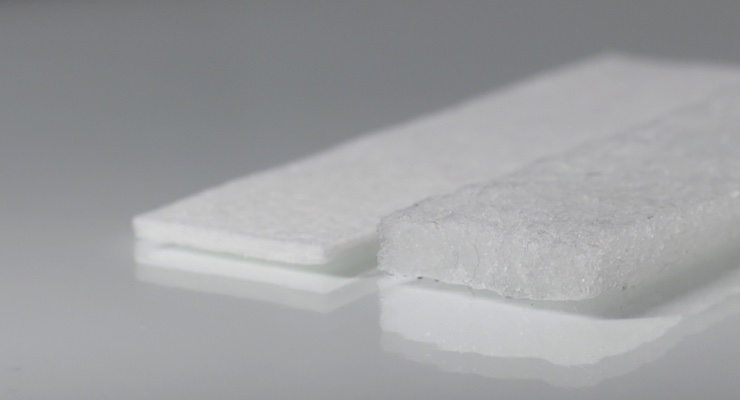

A consortium of five Egyptian researchers have developed the world’s first high performance fibers and reinforcements extracted from the byproducts of pruning of date palms, such as frond and fruit stalks, also known as PalmFil. The fiber is not only sustainable, but also economical in manufacturing, compatible with textile and composite processing and offers the properties needed for lightweight cars of the future. “In the 1980’s the shift from natural fibers to manmade fibers was mainly to bridge the gap between the increasing demand for textile fibers and the limited supply of natural fibers," says Dr. Mohamad Midani, partner, PalmFil Consortium. "In order to reverse this shift, there is a need to explore more sources of natural fibers and increase the biodiversity of fiber crops. Thisis actually what we did, there are more than 140 million date palms mostly concentrated in the Middle East and North Africa, generating yearly more than 4.8 million tons (dry wt.) byproducts of pruning regarded as agriculture waste. This represented a burden on palm growers, and was the main cause of fire accidents and infestation by dangerous insects. Those byproducts could otherwise be transformed into 1.3 million tons/year natural textile fibers, ranking third after cotton and jute.” There has been several previous attempts to extract fibers from date palm byproducts through crushing and grinding, resulting in a biomass rather than textile fibers. PalmFil consortium succeeded in extracting the first long textile fiber from such byproducts and converted it into fiber tow, chopped fiber, spun yarn/ roving, nonwoven mat, woven fabric, and unidirectional tape. The new fiber represents a sustainable material base for a wide spectrum of industries. Ranging from natural reinforcements for composites in automotive and sporting goods, plasterreinforcements in construction, burlap sacks for packaging, ropes, and twines, non-wood papers, and other consumer products. Mr. Dilip Tambyrajah, secretary general, International Natural Fiber Organization, says: "Date palm byproducts have been used for centuries in the Middle East and it is a heritage related material. It is culturally embedded in Middle Easterns but possibly forgotten in modernity. Recent R&D conducted by PalmFil consortium demonstrates the potential of date palm fiber; its use in the modern context and in industrial settings. Revival of the fiber sector in the Middle East will need dedication and national commitment. The use of date palm fiber is not the issue. The use of most natural materials like the date palm fiber contribute towards maintaining biodiversity, provide employment and income and enable sustainable development in general. However, the key to its revival will be the national will and support to encourage the development of a reliable supply chain that can service the various production sectors that could use the fiber." Dr. Ahmed Hassanin, partner, PalmFil Consortium, comments...

read more

0086-15260373015

0086-15260373015 admin@rxhygiene.com

admin@rxhygiene.com English

English فارسی

فارسی français

français русский

русский español

español português

português العربية

العربية Türkçe

Türkçe ไทย

ไทย Việt

Việt